How to Prevent End Cap Strikes

We all dread hearing about end cap strikes and hope it doesn’t happen to us. If it does happen to you, you’re fully covered by our Unconditional Lifetime Warranty. However, we’d all be better off without an end cap strike occurring, so let's get into why they typically happen and how to prevent them on both pistol and rifle suppressors.

General Issues

-Walk Off - Suppressor walk off occurs when your suppressor slowly becomes unthreaded while you’re firing. A great way to prevent this is by wrapping your barrel’s threads a couple times with Teflon tape. Two circulations is a good amount. Be sure the tape does not go onto the shoulder of your firearm.

-Non-Concentric - It is unfortunate that barrels are not always threaded perfectly straight. When this happens, the threads aren’t concentric with the barrel and will cause an end cap strike when a suppressor is attached. If you are consistently getting front cap strikes with a specific firearm, we suggest checking the barrel and suppressor with an alignment rod.

-Bullet Not Stabilizing - In some instances, a bullet won't fully stabilize after leaving the muzzle of the barrel; therefore, it may strike a baffle or end cap while exiting the suppressor. If you’ve never had an issue with a suppressor and host combination, then randomly get a strike (and the suppressor is tight) - this is most likely the culprit.

Pistol Suppressor

- Piston Not Lubricated - Your piston has to be lubricated in order for your pistol suppressor to cycle properly and not cause end cap strikes. We recommend using white lithium grease. Place enough to lightly cover the piston as shown in the photo below.

-O-Rings - At times pistol barrels will come with O-Rings on the threads near the shoulder of the barrel. These are typically used to prevent the thread protector from walking off. It causes misalignment of the suppressor, leading to front cap or baffle strike.

-Not Correctly Attached to 3 Lug Mount - When attaching a suppressor onto a 3 lug mount, always make sure it’s done properly. If the suppressor does not click up into the proper lug, it can come loose and while firing. You can test this by seeing if the suppressor twists or pulls off the 3 Lug Attachment. If it does, reattach it. When attached properly, you should notice it pop up into position and it won’t be able to twist or be pulled off. Our 3 Lug Attachments have a visual Go/No Go Gauge in order to show when the suppressor is properly attached. Check out this video on how to install your 3 Lug Mount.

Rifle Suppressor

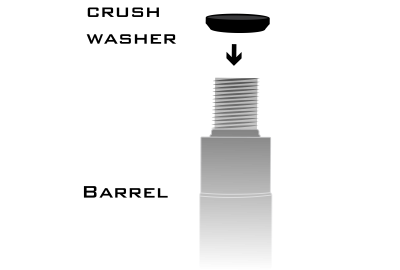

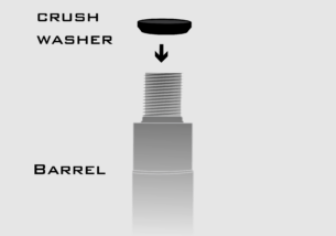

Crush Washers - Crush washers are in between the barrel's shoulder and the muzzle device that comes standard with your rifle. Not all rifles come with them, but a majority do. A crush washer prevents a suppressor from being able to sit flush on the barrel shoulder, which can throw off the alignment. Having a suppressor attached to a rifle with a crush washer is one of the most common reasons we see end cap strikes. Do not use crush washers with Rugged Suppressors, they are not needed.  -Properly Attached Suppressor - Making sure your suppressor is properly secured will prevent multiple issues - including front cap strikes. Rugged Suppressors come with a Go/No Go Gauge in order to visually see that the suppressor is properly attached. For more information on our Dual Taper Locking Mounts and Go/No Go Gauge.

-Properly Attached Suppressor - Making sure your suppressor is properly secured will prevent multiple issues - including front cap strikes. Rugged Suppressors come with a Go/No Go Gauge in order to visually see that the suppressor is properly attached. For more information on our Dual Taper Locking Mounts and Go/No Go Gauge.

Watching out for these issues will prevent 99% of end cap strikes. If for some reason you do get a strike, don't worry, you are fully covered with our Unconditional Lifetime Warranty. Follow this link and we'll take care you: Service Request Check out our selection of Rifle Suppressors and Pistol Suppressors. Learn about what makes us different here Why Rugged Suppressors.